Timberland announced its Q3 2014 CSR performance update. The report showed strong improvement in employee service and in the reduction of the brand’s use of volatile organic compounds but factory compliance was off slightly.

Timberland announced its Q3 2014 CSR performance update. The report showed strong improvement in employee service and in the reduction of the brand’s use of volatile organic compounds but factory compliance was off slightly.

Highlights from this quarter’s performance are as follows, organized by Timberland’s four CSR Pillars: Factories, Climate, Product, and Service. Timberland is owned by VF Corporation.

More detailed performance data and analysis can be found on the Goals & Progress section of Timberland’s Corporate Social Responsibility (CSR) website, http://responsibility.timberland.com.

FACTORIES: Of the 310 active factories at the end of Q3, 33 percent are rated Accepted, which is slightly lower than our Q2 results. For a complete factory list, visit the factories section of Timberland’s Responsbility site. For more about VF’s Compliance audit process click here.

Timberland said it additionally measures suppliers implementation of environmental and social/labor management systems using the Global Social Compliance Programme’s (GSCP) environmental framework and Social Accountability International’s (SAI) Social Fingerprint program. On the environmental side, 61 percent of Timberland’s global footwear and apparel production occurred in factories scoring GSCP Level 2 or higher; and 73 percent of Timberland’s global footwear and apparel production occurred in factories scoring Level 3 or higher in SAI’s Social Fingerprint.

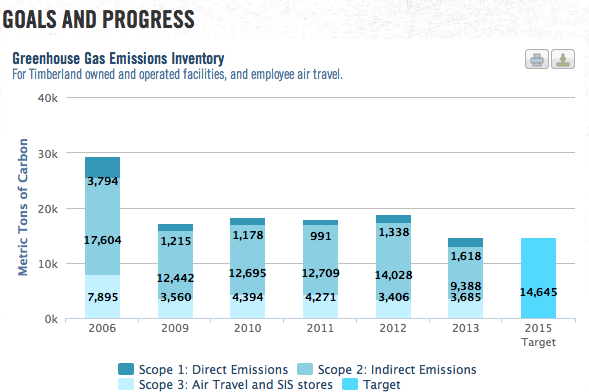

CLIMATE: Since the transition to its parent company’s energy reporting structure, there is a significant delay in obtaining quarterly data of its greenhouse gas emissions and its use of renewable energy. Going forward, Timberland said it will be reporting these numbers externally on a yearly basis, in conjunction with its first quarter reporting. Timberland said it will continue to carefully monitor its energy usage on an internal basis, but does not wish to hold up the reporting of its other CSR metrics. With respect to energy management in factories, 66 percent of Timberland’s global footwear and apparel production comes from factories meeting GSCP’s Level 2 for Energy management.

PRODUCT: Timberland’s global average grams of volatile organic compounds used in footwear production is 4.4 fewer grams per pair over the same period last year; and its use of ROR in apparel was roughly 16 percent of total textile weight. With respect to leather sourcing, 99.6 percent of Timberland’s leather volume came from tanneries scoring Silver or Gold in their Leather Working Group (“LWG”) audit.

SERVICE: Timberland employees served 61,240 hours year to date, a 25 percent increase over the same period last year. YTD Hours Utilization Rate (the percentage of employee service hours used compared to the total available hours according to our Path of Service program) at the end of Q3 2014 was 26 percent vs. 24 percent in Q3 2013. Timberland’s Benefit Utilization Rate (the percentage of employees who serve at least one hour) YTD increased from 55 percent at the end of Q3 2013 to 73 percent at the end of Q3 2014.