Last year Tecnica introduced the FORGE collection of custom heat moldable hiking boots to a targeted group of specialty retailers. The in-store “sit and fit” experience to receive a custom molded boot in 20 minutes resonated with customers, and the retailers were happy to have people coming into their stores for the takeaway experience.

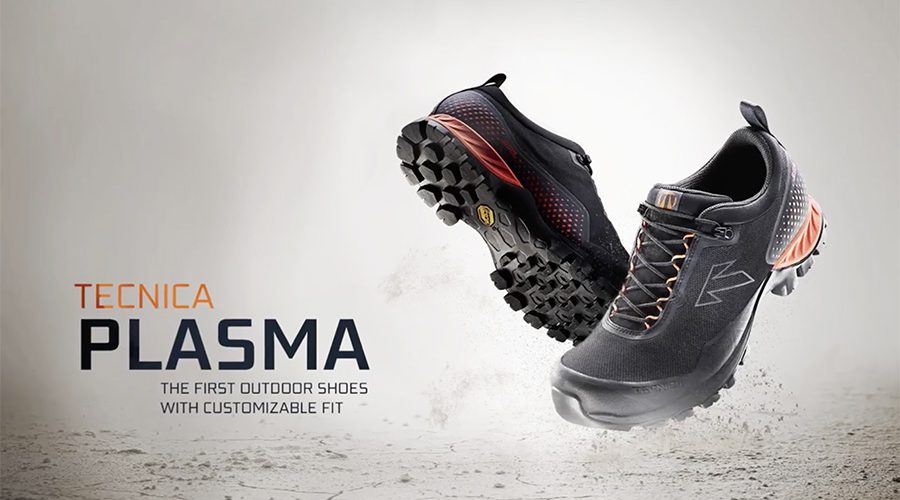

Tecnica introduced at Outdoor Retailer last week the PLASMA S—a low-cut, custom moldable hiking shoe based on the same concept as FORGE—featuring a custom heat-molded footbed and heel/instep area, shown below.

I was curious how the heat molding process worked, so I sat down with Federico Sbrissa, line manager of Tecnica Outdoor, to talk technology and experience the shoe fitting process myself.

My takeaway was simple. FORGE was just the beginning, and all future Tecnica Outdoor products—including the latest PLASMA S—will continue to be created around three pillars: Design, Fit and Versatility.

“For decades we have all dreamed about owning unique, personalized shoes, formed around our own feet. We are all tired of wearing boots that don’t fit or require long break-in times before becoming comfortable. We know that millions of outdoor enthusiasts dream the same, and we wanted to offer them a fast, efficient and affordable solution to own a unique, personalized pair of shoes.” — Federico Sbrissa, pictured left

“For decades we have all dreamed about owning unique, personalized shoes, formed around our own feet. We are all tired of wearing boots that don’t fit or require long break-in times before becoming comfortable. We know that millions of outdoor enthusiasts dream the same, and we wanted to offer them a fast, efficient and affordable solution to own a unique, personalized pair of shoes.” — Federico Sbrissa, pictured left

After lengthy and intensive research into outdoor consumer needs, combined with integrated development between footwear and ski boots, Tecnica combined a precise anatomical fit right out of the box with effective customization capabilities.

Featuring a technology new to footwear, Custom Adaptive Shape or C.A.S. (first used in Tecnica’s alpine ski boots), FORGE and PLASMA S offer a fully customizable, personalized fit in only 20 minutes.

<span style="color: #808080;">Tecnica is one of the few companies in the Montebelluna region of Italy that continues to design, develop and prototype ski boots, skis and shoes because they own the factories. The story behind “personalized fit” started a little over two years ago. But let’s take a trip back in time, because to understand today, you have to know the roots of Tecnica.

Since the 1950s, the Tecnica family has been manufacturing winter outerwear shoes in Montebelluna. Around the 1980s, when there was a big trend around winter sports and skiing, the Tecnica family decided to invest in making ski boots and eventually they became one of the biggest players in the ski boot industry.

Over the years, the company has shifted to manufacture footwear for the outdoor winter sports enthusiast for one reason. The family has always had a passion for skiing, and the shoe business was never as successful for the brand, especially not in the U.S., where the business fluctuated up-and-down.

<span style="color: #808080;">Two years ago there was a relaunch at Tecnica. The company invested time and money to bring a new team on-board and develop a new footwear concept. The brand wanted to make something that made sense for the trends and aligned with what the consumer wanted and which made sense for the market.

What were the important factors to bring the “custom fit” collection to market? First, consumers and retailers. We wanted to make one, single concept that was very meaningful for both and for specialized distribution. Two, to make a fully customizable fit with zero break in time right out of the box.

The timing sounds like it was perfect. At that time our outdoor distribution was struggling a bit because of the internet, Amazon, etc. We wanted to build a concept which was sensible for consumers but that also happened at the retail level. The goal is, and continues to be, for customers to go to specialized retailers and get fitted from the box and out on the trail the same day with no break in time.

What has the feedback been from retailers? Overwhelmingly positive because they were waiting for something unique where they could use their expertise to provide a good fit, make the customer happy and see results from the good fit experience. We are just introducing the technology worldwide; it will take time, but we are convinced it will change the outdoor shoe fitting process.

Briefly, how does the fit process work? Very simple. We developed a machine which is able to heat by temperature two items–the footbed that comes with the shoe, so it is fully customizable, and the upper. The machine’s heater softens the key areas of the footbed and shoe–heel, arch, ankle and footbed. The compression system housed in the machine reshapes the heated footbed and boot while the customer is in the shoe to provide a customized fit to the anatomy of the foot similar to casting.

The special material inside the shoe is heat-activated by the machine, which means that the material—after heating—becomes soft, and as soon as the material gets cold, it becomes rigid again. That is the secret. It’s what we call a Thermoformable material, which is similar to a TPU plastic, but it has a lower activation point so you only need to warm up the shoe to 160 to 180 degrees for the material to become pliable, and it cools down very quickly. Within about three minutes, we are able to get the shape of the foot/shoe. The material is a TPU, but has fibers within the structure so that even in extremely cold temperatures, the material will not fracture.

I wear prescription orthodics. Will we fit the shoes with them or without today? Our customizable footbed will follow the natural shape of your foot but it is not a corrective item. In your case, I would recommend for you to use your orthodics, but let’s see them before we start the heat molding process to fit you for a pair of FORGE Hiking Boots. Looking at them, I think we will be OK to fit you using the footbed that comes in the FORGE.

The fitting steps are as follows: The footbed is removed from the boot and slipped into a soft shell liner, shown below; then your foot goes into the liner and both are sandwiched together. Your legs are velcro’d together at the knees for three minutes while the machine works it magic to heat up the insoles and mold to your foot.

Next, your foot and molded footbed are slipped into the boots, and the process repeats with your knees in velcro while the machine works it’s magic to apply heated pressure to the key areas of the shoe, shown below.

In just three minutes, your feet are custom-molded in the boot and you are good to go. Still skeptical, I hit the trails here in Boulder when I got home from the Show. Bye-Bye Orthodics!

The most comfortable boots are the ones that you don’t even realize you have on your feet. And, this year, in plenty of time for fall and winter, I have the most super-comfortable pair of boots to wear on the trail. Need I say more?

Photos courtesy Tecnica