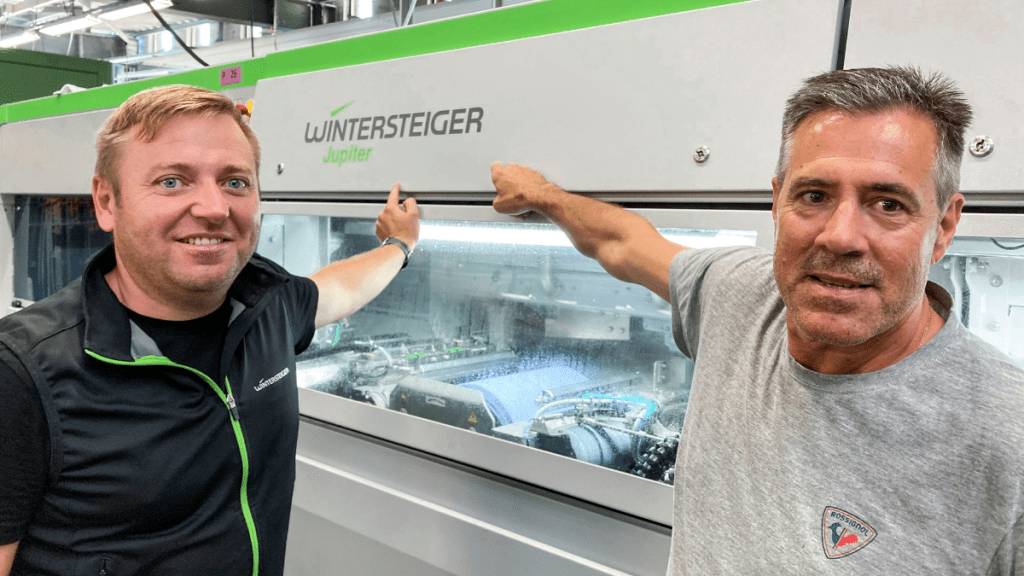

Rossignol Group, home to global winter sports brands Rossignol and Dynastar, said it invested in Wintersteiger Jupiter ski service machines for its three production centers in France and Spain to process the Group’s racing ranges and consistently finish across all its facilities.

“Rossignol Group brands have trusted in Wintersteiger machines for ski finishing for many years now. Having run successful quality and stability tests, we have decided to fit new Jupiter ski service machines at our three production sites in Artes, Sallanches and Moirans for our race skis and junior race ski range,” explained Antoni Jimenez, Rossignol Group’s purchasing director.

“The new investments in our production race lines, including the Wintersteiger Jupiter machines, have proven to produce some of the best finishing we have seen,” said Thor Verdonk, technical product manager, Winter Sports Equipment, Rossignol Group. “We have been very excited and pleased with the precision and cleanness of the finish.”

Introduced in 2021, the Jupiter is the latest Wintersteiger automated machine with solutions available for snowsport service, including Ceramic Disc Finish for a precise and consistent edge, Trim Cut for automated side wall preparation, V-Edge for variable edge angles for the base, side edges and length of skis, 3D structures for all racing requirements, and QR scanner for automatic ski recognition.

Rossignol Group said, “over 40,000 pairs of Rossignol and Dynastar racing skis have been serviced at the three production facilities. In the Moirans Racing Department factory, Rossignol is using extremely positive feedback from their athletes to prepare skis for the upcoming World Cup start in Soelden, where the innovative V-Edge technology will open new possibilities in edge tuning that can help racers achieve their maximum potential.”

Photo courtesy Rossignol Group