Bethel, CT, September 8, 2020 – This week, Altexa srl and GHS Holdings announced the launch of the HDry® brand in North America. HDry is the most advanced technology for waterproofing outdoor products through direct (3D) lamination of a waterproof/breathable membrane.

HDry’s entrance into the North American market means more options for brands looking for a partner in the creation of high-performance, waterproof technology for gloves, footwear and packs. HDry strengthens the technological development that Altexa founders initiated in 2006 when they first created the OutDry technology and brand.

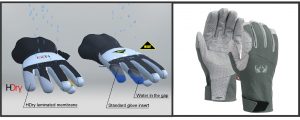

HDry waterproof breathable membrane is directly applied to the inner side of the outermost layer by a patented 3D lamination process that is seamless and tapeless. The direct lamination of the membrane eliminates drawbacks associated with other “free-hanging” glove and shoe inserts on the market and offers a higher performance solution that cannot be matched by traditional waterproof systems.

Gary Schloss, CEO of GHS Holdings spearheading HDry North America, shares his perspective, “I am very excited to be a part of bringing the HDry brand overseas, I have been involved with this technology and the group at Altexa since 2008 and firmly believe in the company’s mission and the technology itself. Schloss adds, “Having worked with apex brands like Patagonia, Black Diamond and Mountain Hardwear on design and development for technical wear for the better part of 40 years, I know full well the advanced performance characteristics that this 3D seamless bonding technology offers for brands looking for a premium waterproof and breathable solution. I look forward to also working with footwear and backpack brands to show how HDry can take their products to the next level.”

The excitement is equal for Matteo Morlacchi, CEO and founder Altexa srl, owners of HDry technology, “The collaboration with Gary Schloss to launch HDry technology and brand in North America is quite natural as, in 2008, he was one of the first to believe and invest in the high potential of the direct membrane lamination technology that we had just developed at the time. Considering his experience and reputation in the glove industry, this was ideal support. With the same technology now further refined and improved, we look forward to seeing strong growth in the US and Canadian market.”

HDry is committed to its role in protecting the environment. Their innovative manufacturing processes and materials used throughout the lamination process are well above industry standard and aim to reduce the environmental footprint of the outdoor and apparel manufacturing industries. The HDry compound is made by a polyurethane ester-based waterproof/breathable membrane combined with thin polyester knit. Material saving and lightness are the greatest advantages. HDry is absolutely PTFE-free and no perfluorinated compounds (PFCs, PFOS, PFOA etc.) are used in its production. HDry does not contain any substance of REACH – ECHA list.

The ‘HDry’ brand derives from the abbreviation of the chemical name for water (H2O), coupled with the word ‘Dry’, and signifies the affinity between this technology and water.