[et_pb_section admin_label=”section” transparent_background=”off” background_color=”#ffffff” allow_player_pause=”off” inner_shadow=”off” parallax=”on” parallax_method=”off” padding_mobile=”off” make_fullwidth=”off” use_custom_width=”off” width_unit=”on” make_equal=”off” use_custom_gutter=”off” background_image=”https://sgbonline.com/wp-content/uploads/2016/10/LAYOUT_Cole-Wiliams-at-work.jpg”][et_pb_row admin_label=”row” make_fullwidth=”off” use_custom_width=”off” width_unit=”off” use_custom_gutter=”off” padding_mobile=”off” allow_player_pause=”off” parallax=”off” parallax_method=”off” make_equal=”off” parallax_1=”off” parallax_method_1=”off” column_padding_mobile=”on” custom_width_percent=”100%”][et_pb_column type=”4_4″][et_pb_post_title admin_label=”Post Title” title=”on” meta=”on” author=”on” date=”on” categories=”off” comments=”off” featured_image=”on” featured_placement=”background” parallax_effect=”on” parallax_method=”on” text_orientation=”center” text_color=”light” text_background=”off” text_bg_color=”rgba(255,255,255,0.59)” title_text_color=”#ffffff” title_all_caps=”off” meta_text_color=”#ffffff” use_border_color=”off” border_color=”#ffffff” border_style=”solid” title_font=”Crimson Text|||on|” title_font_size=”34px” module_bg_color=”rgba(255,255,255,0)” meta_font=”||on||” title_line_height=”1.1em”] [/et_pb_post_title][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section admin_label=”Section” fullwidth=”off” specialty=”off” transparent_background=”off” background_color=”#ffffff” allow_player_pause=”off” inner_shadow=”off” parallax=”off” parallax_method=”off” custom_padding=”0px||0px|” padding_mobile=”on” make_fullwidth=”off” use_custom_width=”off” width_unit=”on” make_equal=”off” use_custom_gutter=”off”][et_pb_row admin_label=”Row” make_fullwidth=”on” use_custom_width=”off” width_unit=”on” use_custom_gutter=”on” gutter_width=”1″ padding_mobile=”on” allow_player_pause=”off” parallax=”off” parallax_method=”off” make_equal=”on” parallax_1=”off” parallax_method_1=”off” parallax_2=”off” parallax_method_2=”off” column_padding_mobile=”on” custom_padding=”0px||0px|” custom_width_px=”680px”][et_pb_column type=”4_4″][et_pb_text admin_label=”Text” background_layout=”light” text_orientation=”left” use_border_color=”off” border_color=”#ffffff” border_style=”solid” custom_margin=”25px||25px|”]

Waterproof socks and gloves fall into the category of products you don’t know you need until you need them. Fly-fishing in a frigid stream, knee-deep in water, hands struggling to untangle line or manipulate equipment, the thought of warm, dry extremities becomes vividly alluring.

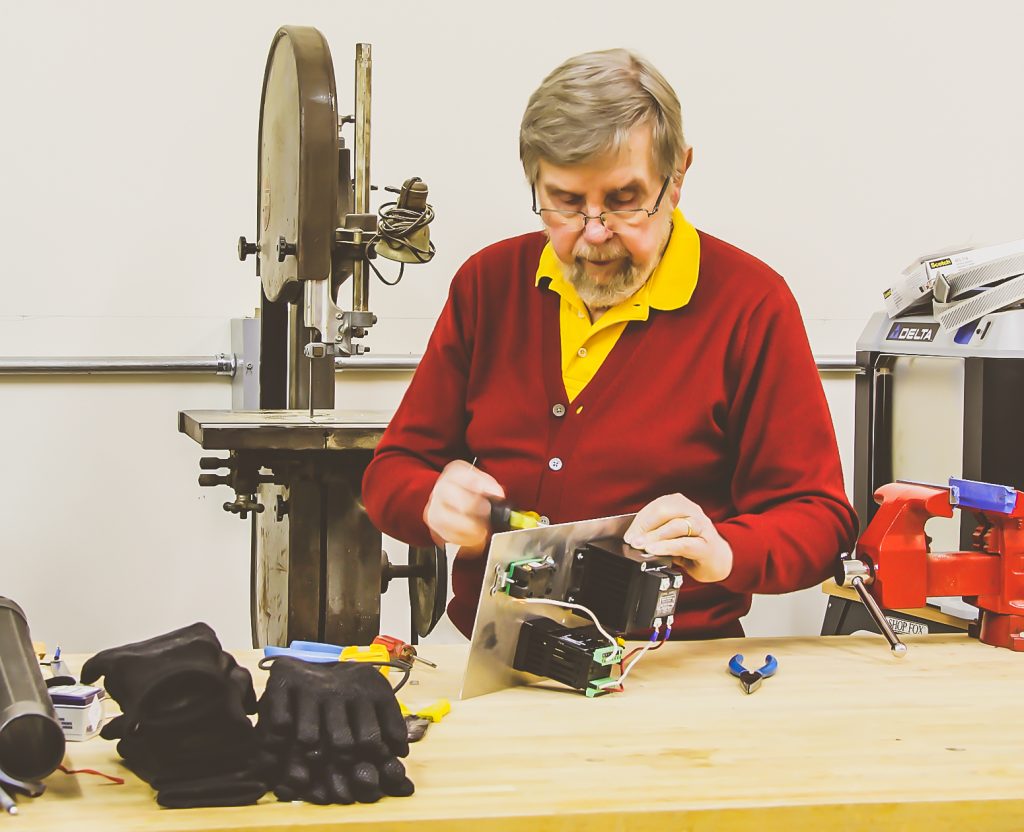

That’s the idea behind Hanz Extremity Wear, hatched in 1970, with the company’s first completely waterproof socks introduced to the outdoor industry in 1993. Founder Cole Williams is now in his 80s, a lifelong inventor, designer and manufacturer and still involved in Hanz operations, although he now shares the responsibility with his daughter Amy Williams, current president of the company.

Cole Williams’ unusual and wide-ranging career found him designing model airplanes for Cox Thimble Drome and later serving a lengthy stint developing medical supplies for corporate giant Dupont. Between high school and college, Williams spent a summer in Alaska working in a gold mine and riding his bike on the then all-dirt Alaska highway. “Danalco,” which eventually became Hanz, “is the second company I’ve started in my garage,” said Williams of his entrepreneurial bent. The first produced the Desert Rat personal utility vehicle he independently manufactured in the early 1960s.

After more than 20 years in the outdoor industry, Hanz now produces a diverse line of waterproof gloves and socks, including calf-length Submerge socks that stay dry even when completely underwater. “I’ll listen to anyone,” said Williams about his innovation process. “A lady in the Midwest had a daughter who needed socks for swimming…I told her they would fill up with water, and then she swore at me like a sailor and hung up. That led to the development of Submerge.”

[/et_pb_text][et_pb_image admin_label=”Image” src=”https://sgbonline.com/wp-content/uploads/2016/10/LAYOUT_Desert-Rat-Mt.-Alyeska-AK-1963.jpg” show_in_lightbox=”off” url_new_window=”off” use_overlay=”off” animation=”off” sticky=”on” align=”left” force_fullwidth=”off” always_center_on_mobile=”on” use_border_color=”off” border_color=”#ffffff” border_style=”solid”] [/et_pb_image][et_pb_text admin_label=”Text” background_layout=”light” text_orientation=”left” use_border_color=”off” border_color=”#ffffff” border_style=”solid” text_font_size=”12″ custom_margin_last_edited=”on|”]

Desert Rat Mt. Alyeska, AK 1963

[/et_pb_text][et_pb_text admin_label=”Text” background_layout=”light” text_orientation=”left” use_border_color=”off” border_color=”#ffffff” border_style=”solid” custom_margin_last_edited=”on|”]

Simple solutions to simple problems are at the root of the brand’s identity. “People still need socks,” Williams pointed out, “and our product is excellent. Now we need to re-establish our brand.” Amy Williams agreed “the message we want to convey is simple. Waterproof socks. Waterproof gloves. Touchscreen gloves.” She wants Hanz products to be the one of the “ten essentials” you throw in your trunk and leave there in case conditions or plans change.

The father-and-daughter Williams team runs Hanz from the company’s headquarters north of Seattle, and the entire manufacturing operation is in Duarte, CA. The upside of producing products in the U.S. includes “good quality assurance and quick turnaround.” Williams likes being able to turn an order around in a few weeks, and thinks it’s especially important for a company to have control over its operations and distribution. Plus, by buying domestic, “You’re more likely to be treated well, consistently well.”

As far as limitations, Williams mentioned there are fewer yarn spinners around than in the past, which he attributes to a declining U.S. textile industry. This limits the number of vendor choices. However, like other Made in the U.S.A. active and outdoor companies have found, winning military contracts is that much easier when your operation is stateside. Mentioning the Berry Amendment that has the likes of New Balance and Wolverine Worldwide moving more of their manufacturing to the U.S., Williams stressed that “not just you but also your suppliers must comply.”

[/et_pb_text][et_pb_image admin_label=”Image” src=”https://sgbonline.com/wp-content/uploads/2016/10/LAYOUT_contact.us_.jpg” show_in_lightbox=”off” url_new_window=”off” use_overlay=”off” animation=”off” sticky=”on” align=”left” force_fullwidth=”off” always_center_on_mobile=”on” use_border_color=”off” border_color=”#ffffff” border_style=”solid”] [/et_pb_image][et_pb_text admin_label=”Text” background_layout=”light” text_orientation=”left” use_border_color=”off” border_color=”#ffffff” border_style=”solid” custom_margin_last_edited=”on|” custom_margin=”25px|||”]

But the bulk of Hanz’s customers aren’t in the military, nor are they represented by Williams’ vote for most bizarre product use: an equine dentist who “loved the elbow-length gauntlet glove” when he was similarly elbow-deep in horse mouth. Hunters, fishermen and, increasingly, paddle sports enthusiasts are the brand’s target audience – people who enjoy activities that take place almost exclusively in thermally challenged environs.

“Early on, a number of adventure racers found that our socks could contribute to their success by reducing foot injury due to grit and water,” explained Amy Williams. “We’ve loved hearing from folks using the waterproof socks and gloves for all sorts of things ever since.” Both father and daughter see themselves as designers and manufacturers rather than brand marketers, so “we’re happiest when others are recognizing the benefits of our products,” she added.

The elder Williams credits his daughter with ushering Hanz’s latest advance – touchscreen-compatible waterproof gloves – through development at the R&D workshop. “I’m working on listening and responding to comments Amy brings home,” he said. “People would say to her, ‘I’d buy that if it had touchscreen,” so the team got to work.

The compatibility technology, which combines an electrically insulating membrane with Tap-Knit touchscreen-friendly yarn, is “more economical” than what already existed in the market. The touchscreen gloves are “brand new,” but Williams is excited about their adoption. “Part of my task is to refine these things,” he added, hinting that an inventor’s job is never done.

His active role in the company brings a lot of enjoyment, even at his age. “I’m afraid of retiring,” he joked, adding that his wife sometimes refers to Hanz as his mistress. “For an old man to listen to new ideas…I enjoy it.” He’s still cooking up new innovations and applications, especially gloves for doctors and nurses that self-sterilize between patients. “That’s a dream that I don’t have an answer for…yet,” he said.

Photos courtesy Cole Williams

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]