<span style="color: #999999;">Toray Industries has created a new nylon textile using the textile manufacturer’s NanoDesign technology. Despite using a DWR treatment (with lower environmental cost), the latest innovation from the giant delivers high water repellency.

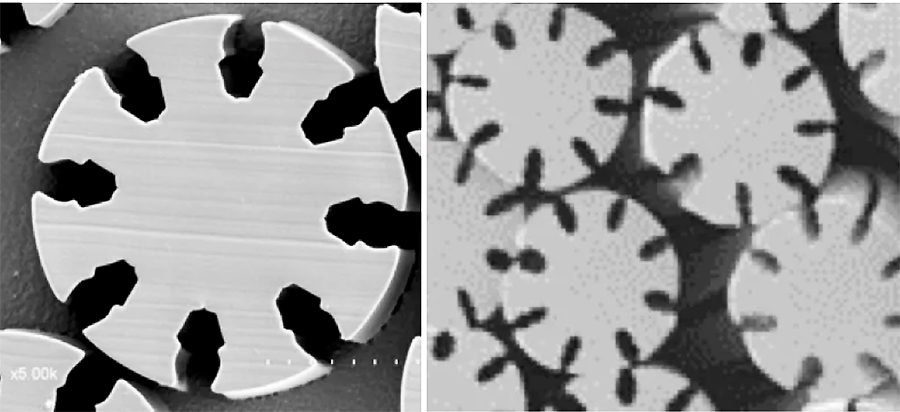

How? The textile’s structure has microscopic slits running lengthwise on the yarn. Water-repelling treatments fill these slits below the outside diameter of the yarn, also making the treatment more abrasion-resistant.

How? The textile’s structure has microscopic slits running lengthwise on the yarn. Water-repelling treatments fill these slits below the outside diameter of the yarn, also making the treatment more abrasion-resistant.

The result offers two benefits. First, the construction enables the textile to use C6 water repellents, which are normally insufficient for outdoor sports and Second, the textile provides more resistance to abrasion, which is a leading contributor to diminishing DWR performance.

Despite the slits, the textile has the strength and abrasion-resistance of other yarns and is processed the same way.

<span style="color: #999999;">Fluorine-based water repellents used in the past do not easily decompose naturally because of their stable chemical structure. They also contain Perfluorooctanoic Acid, PFOA, also known as C8, which could accumulate in the body and also remain in the environment. With growing concerns on these two factors and a need for materials using water repellants with low environmental harm, the use of C6 offers this and does not contain PFOA.

Toray’s textile innovation will be market-ready Fall 2020 as a material variation of the existing textile brands Airtastic®, ENTRANT® and Dermizax® and marketed to manufacturers in the active lifestyle, ski and athleisure space for the textile’s high water repellant properties. In North America, Toray International America, Inc. will provide the latest textile technology.

Photos courtesy Toray Industries, Inc.