The University of California San Diego (UC San Diego) and Algenesis Corporation, a material science company, published a scientific study in the fight against microplastic pollution.

The study, titled “Rapid biodegradation of microplastics generated from bio-based thermoplastic polyurethane,” published this week in Nature’s Scientific Reports, is a collaborative effort among researchers from Algenesis and UC San Diego, including Marco Allemann, Marissa Tessman, Jaysen Reindel, Gordon Scofield, Payton Evans, Robert Pomeroy, Michael Burkart, Stephen Mayfield, and Ryan Simkovsky.

The study showcases the development of a bio-based and biodegradable thermoplastic polyurethane (TPU) that promises to “significantly reduce the environmental and health impacts of plastics and address one of the most pressing environmental challenges of our time: microplastic pollution.”

The new material is the latest product from Algenesis’s Soleic brand of polyurethane materials, which will be available this year in applications including coatings and injectable plastics.

Microplastics are tiny, nearly indestructible fragments shed from everyday plastic products and that have accumulated in our oceans, ecosystems and within us. Recent studies published in the New England Journal of Medicine and Toxicological Sciences have demonstrated the presence of microplastics in human placentas and heart plaques, which are associated with increased mortality. The findings point to an urgent need to remove microplastics from the environment while adopting sustainable materials that do not produce persistent microplastics.

Algenesis’ latest breakthrough is the development of a bio-based TPU. In its study, Algenesis demonstrates that tiny plastic particles from this new TPU can rapidly biodegrade under home composting conditions.

For the study, they generated microplastics from the TPU material using a belt sander and then studied how the particles biodegrade in the natural environment. They discovered that even common soil microorganisms can grow on the microplastics and use them as their sole carbon source. These bacteria eat the transient plastics, turning them into harmless nutrients and carbon dioxide, ensuring these materials won’t leave lasting microplastic waste in the environment.

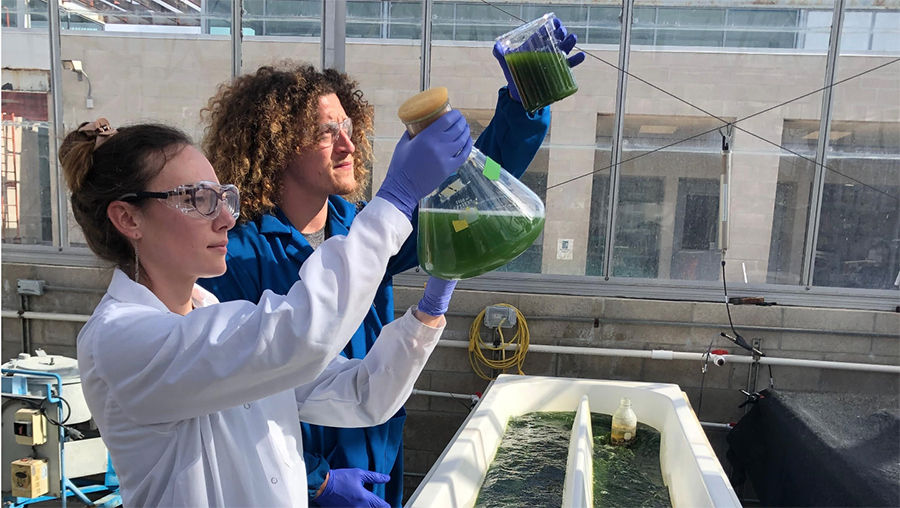

Co-founded by a trio of UCSD scientists—Stephen Mayfield, Michael Burkart, and Robert “Skip” Pomeroy—Algenesis is helping to lead sustainable material innovation, with previous developments including foams that biodegrade in compost, soil and marine environments. The foams are in the company’s shoes through its direct-to-consumer brand Blueview Footwear and in products developed via the company’s B2B materials brand, Soleic, including coated fabric made by Trelleborg and phone cases made by RhinoShield, available later this year.

Co-founded by a trio of UCSD scientists—Stephen Mayfield, Michael Burkart, and Robert “Skip” Pomeroy—Algenesis is helping to lead sustainable material innovation, with previous developments including foams that biodegrade in compost, soil and marine environments. The foams are in the company’s shoes through its direct-to-consumer brand Blueview Footwear and in products developed via the company’s B2B materials brand, Soleic, including coated fabric made by Trelleborg and phone cases made by RhinoShield, available later this year.

“The petroleum plastic products that are all around us now, including recyclable plastics, are constantly shedding microplastics through daily use, wear and tear, and the recycling process itself. Even though they are tiny, they don’t go away at the molecular level and because microplastics are so small, they are the most difficult form of plastic pollution to clean up,” said Ryan Simkovsky, chief technology officer for Algenesis and the corresponding author of the publication. “Through a combination of direct visualization, respirometry, microbiology, and analytical chemistry, our team has demonstrated that if or when our Soleic plastics generate microplastics, they will only be transient in nature and will rapidly decompose in the environment because common microorganisms are capable of biochemically eating them as nutrients. This has to become the future of all plastics, as we simply cannot continue to pollute our planet and our bodies with microplastics.”

The study further illustrates the material’s practical applications through the creation of TPU-coated cotton fabrics and injection-molded phone cases, both of which meet physical specifications for commercial products. Both applications underwent rigorous testing, showing clear structural degradation and significant biofilm formation, indicating real-world biodegradability.

Algenesis’ partnership with Trelleborg underscores the material’s versatility and potential to disrupt industries ranging from aerospace applications to outdoor apparel.

“Trelleborg aims to develop a range of eco-friendly polymers and production processes that align with the growing demand for sustainable materials in various applications,” added Steve Brockman, Trelleborg business unit president.

“Our collaboration with Trelleborg enables us to bring this cutting-edge material to market, offering consumers sustainable alternatives that don’t compromise on quality or performance,” added Stephen Mayfield, CEO of Algenesis.

RhinoShield, a leading tech accessories producer, will launch a Soleic injectable smartphone case made from the new bio TPU material. “RhinoShield is looking forward to teaming up with Algenesis to tackle the world’s plastic issue. We’re equally enthusiastic about establishing sustainable standards for the phone case industry,” said Eric Wang, CEO of RhinoShield.

Algenesis’ biodegradable TPU material represents a leap forward in reducing the production and accumulation of microplastics, safeguarding the Earth’s ecosystems and human health. This innovation aligns with Algenesis’ mission to “lead the way in creating materials that are not only high-performing but also inherently kind to the planet.”

Images courtesy Algenesis