Karuishi is a knit textile from Toray that represents a “significant improvement to date in the fleece fabric category,” said Toray.

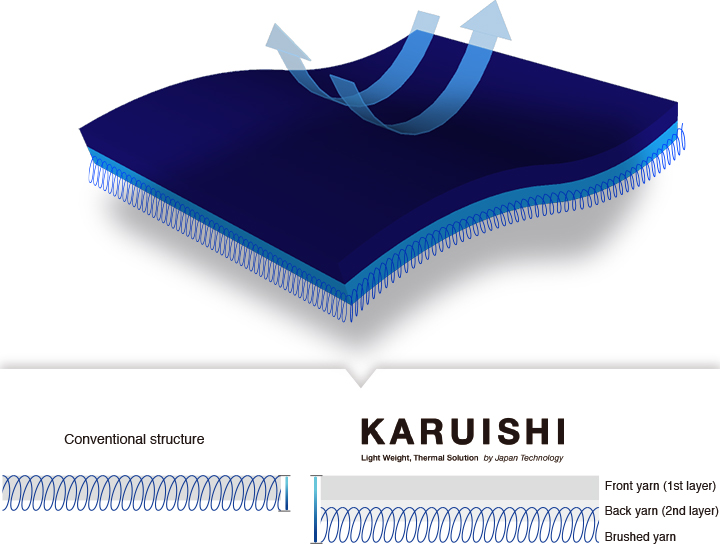

To create Karuishi, the textile manufacturer developed a knitting construction that creates a high-volume, two-layer structure resulting in a higher loft without increasing weight.

- The knitting method allows Toray to use variations of yarns on the face and back creating fabrics with different performance characteristics without using glues or laminates.

- Karuishi also has a more durable face that resists pilling and abrasion without surface treatment or resins.

Recent testing from Toray has shown another positive and important attribute of Karuishi — it produces a lower level of microplastic shedding by comparison to other leading fleece products.

Toray’s testing labs repeatedly washed samples of Kariushi, as well as competitive fleece, including the outdoor industry’s leading stretch fleece. The lint shed by each fabric was collected and compared. Kariushi fleece showed far less microplastic shedding, especially after repeated washings.

In addition to its performance advantages, testing proves Kariushi to be a better choice for environmental concerns.

Fleece fabrics were an immediate success upon hitting the market in the late ’70s, offering lighter weight, faster drying and easier washability. However, problems with pilling, abrasion resistance and, most recently, significant levels of microplastic pollution have challenged textile companies to develop improvements ever since.

Since its introduction in 2017, Karuishi has proven popular as a more technically advanced fleece for premium products in the outdoor and recreational markets. As brands become more responsive to consumer demand for more environmentally responsible products, expect to see more products using Karuishi arriving at retail.