Tian Li, a post-doc student at the University of Maryland and Liangbing Hu, pictured below, have developed a new material called Nanowood, with the potential to massively reduce waste around the world.

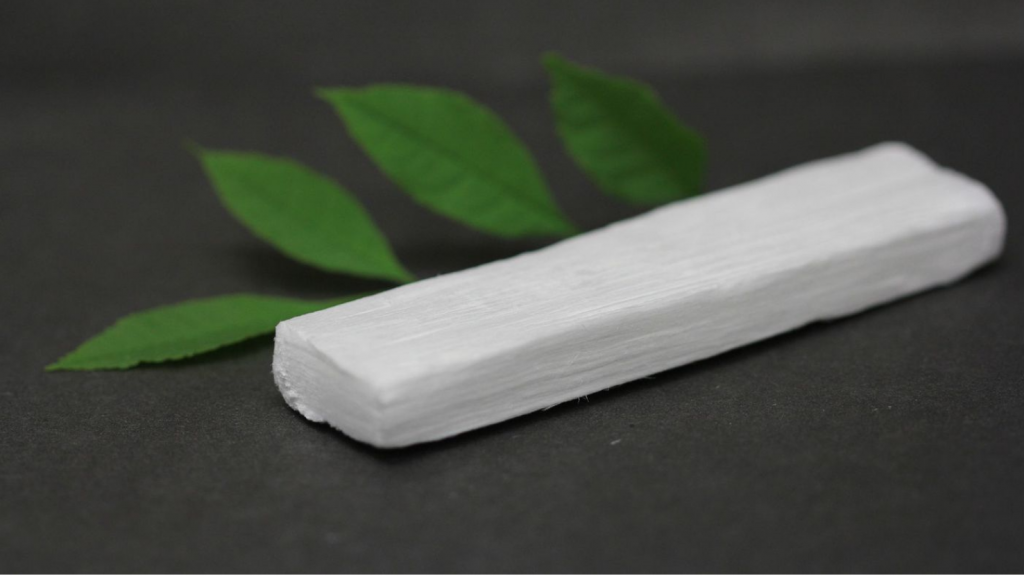

Nanowood does not contain lignin—the ingredient in wood that makes it brown and rigid. The substance is under 1mm thick and can be folded and bent with the potential to replace styrofoam, which takes 500+ years to biodegrade. Nanowood is 30 times stronger than styrofoam, is biodegradable and can insulate better than silica aerogel by 10ºF.

…[the team] has been probing the properties of nanocellulose, nanometer-scale versions of cellulose, the tough carbohydrate in the cell walls of plants that allows tree trunks to grow strong and tall. At these incredibly small scales, cellulose fibers can take on remarkable characteristics, including a strength-to-weight ratio that’s about eight times that of steel.

The key is the design. As the University of Maryland states:

Wood “conducts” heat along the channels that were used when the tree was alive to shuttle water and nutrients from roots to leaves. However, heat trying to cross the wood grain is blocked. With the wood oriented in the right direction, heat could be blocked or transmitted as the designer desires.

Nanowood could be the future of building material with applications in the active lifestyle category.

Photos courtesy University of Maryland