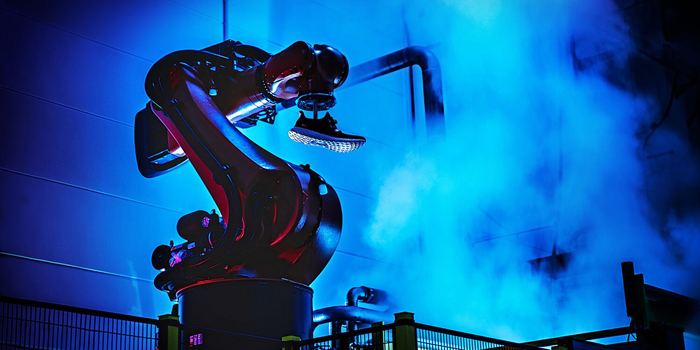

Adidas and Siemens announced their intention to collaborate in the digital production of sporting goods. As part of a joint research and development program, the partners will be working to drive forward the digitalization of the Adidas Speedfactory to ultimately develop capabilities for fast, transparent and individualized production.

The Adidas Speedfactory opens doors for the creation of products which are more closely in touch with the consumer and are completely unique to their fit and functional needs, according to a statement. The manufacture of individual sporting goods calls for flexibility in production and rapid integration of new technologies. As a leader in digital factory automation and simulation solutions, Siemens is bringing invaluable expertise to the table. A “digital twin” of the Speedfactory will allow the entire production process to be simulated, tested and optimized up front. Merging the virtual and real worlds will help shorten the time to market, bring greater flexibility and provide improved manufacturing quality and efficiency.

“Everything we do is focused on our consumers. They demand the highest level of individuality and quality. With Speedfactory we can completely rethink conventional processes and live up to these high expectations,” explained Gerd Manz, Vice President Technology Innovation at Adidas. “By digitalizing the value chain, we will be able to implement new technological innovations more quickly, make more efficient and transparent use of the resources available and so respond more flexibly to the individual needs of our consumers – to give them what they want when they want it.”

“The Speedfactories run by Adidas are a perfect illustration of where the production of the future is heading,” said Klaus Helmrich, member of the management board of Siemens AG. “The social trend towards greater customization coupled with new technologies capable of actually fulfilling these expectations will permanently change many production processes.”

Photo courtesy Adidas