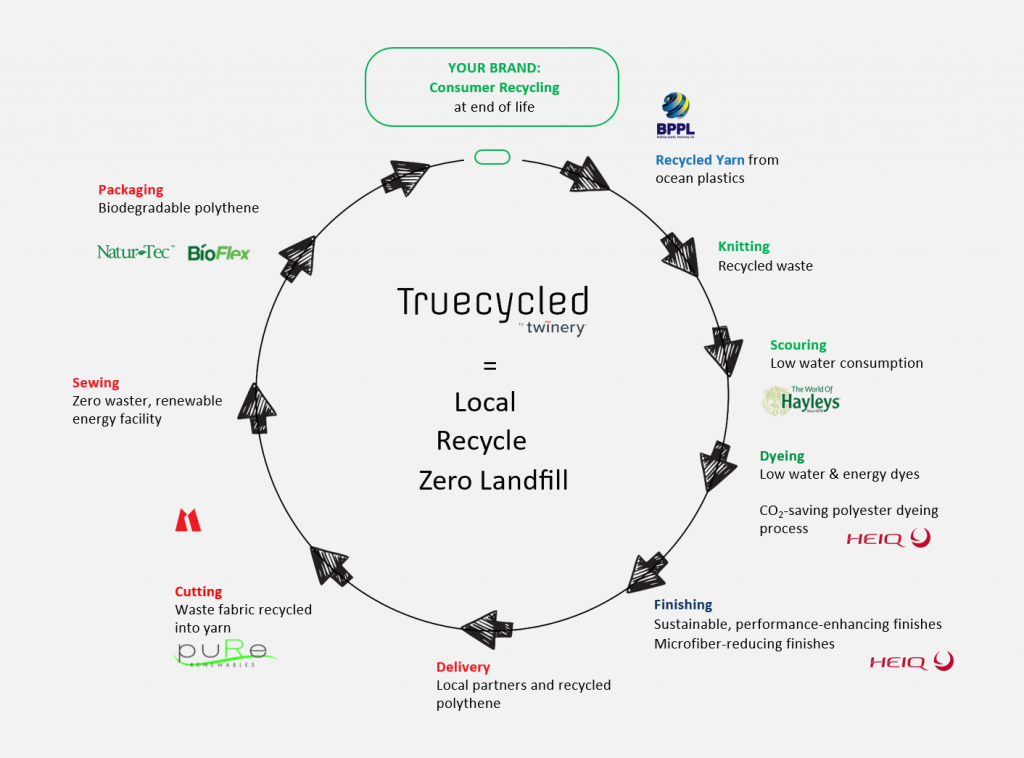

Apparel manufacturing is the second largest polluting industry in the world. While there are many solutions to this problem, Bodyline has taken the lead to focus on developing a low impact supply chain by reducing energy and waste across the entire value chain and develop No Waste Apparel – Truecycled.

Two steps in this supply chain lifecycle include improving the dyeing and finishing stages. To improve the dyeing stage by using less water and energy and save CO2 during the polyester dyeing process, Truecycled has implemented HeiQ Clean Tech for more efficient and ecological processing of textiles.

“Aiming to improve the everyday products of textiles by making them more functional, comfortable and sustainable, HeiQ is proud to partner with Bodyline on their Truecycled project”, says Carlo Centonze, Chief Executive Officer at HeiQ.

Switzerland is a leader in the global innovation economy and Swiss enterprises are very good at combining sustainable economics with commercial interests. This strategy is awarded annually in the selection of the Swiss Environmental Award (“Umweltpreis der Wirtschaft Schweiz”) during the CE2 Days of the Swiss Economic Forum. After several rounds of review, the finalist that are chosen are not only industry leaders, but also outstanding representatives of Swiss innovation and technology. In 2019, HeiQ won the Swiss Environmental Award for the development of its environmentally-friendly HeiQ Clean Tech sustainable polyester dyeing system.

“We are very excited about our Truecycled projects and proud to announce that we have commercialized HeiQ Clean Tech with ODLO as part of this project”, says Dilshan Mohamed, Director at Bodyline. “This is one step in our goal towards Zero Waste Apparel”.

To learn more about HeiQ Clean Tech and the other sustainable products offered by HeiQ, visit heiq.com

Lead Image: Truecycled supply chain lifecycle including HeiQ’s sustainable dyeing and finishing solutions